This tutorial will transform a generic Kato Mikado into a CB&Q O-4 Mikado using GHQ pewter detail parts. I will be detailing one generic "unlettered" Kato Mikado #5506. This is one of the easiest GHQ detail kits to work with. You must download the instructions online as there are no instructions in the kit. However, the downloaded instructions are excellent and the pewter detail parts are very identifiable. This locomotive was fun to detail and finish. This detail kit is still readily available at GHQ 's website listed below.

http://www.ghqmodels.com/

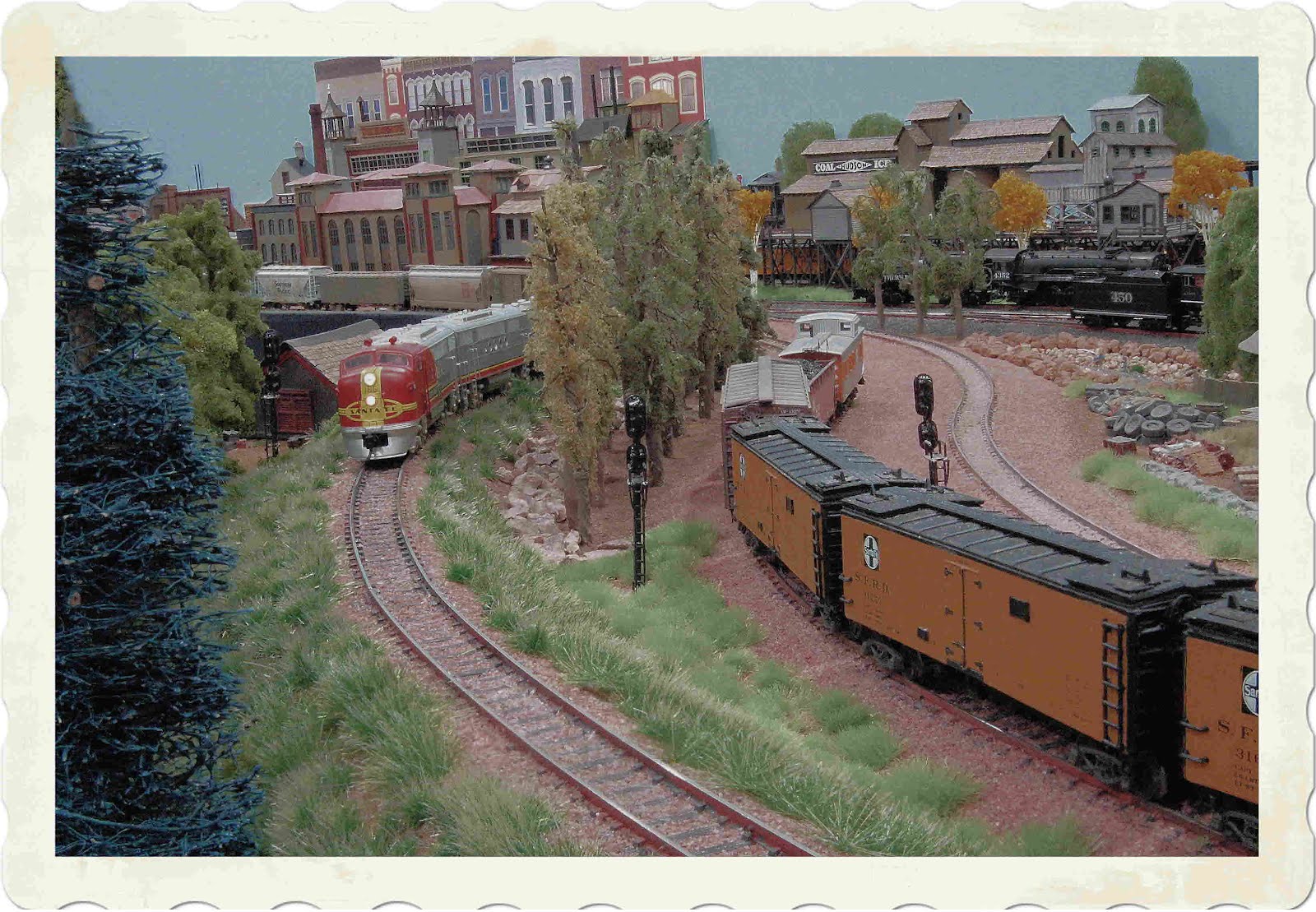

Photo # 1 A view of the boiler showing the pewter detail castings of the CB&Q O-4 Mikado on the mainline east of San Marino in the Monterrey Mountains.

Photo # 2 A closeup view of the CB&Q O-4 Mikado on the engineers side of the locomotive showing all the detail parts. The CB&Q Mikado is slowly climbing the long 1 1/2% grade east of San Marino in the Monterrey Mountains.

Photo # 3 A full view of the CB&Q #5506 O-4 Mikado on the engineers side showing all the detail parts added. The San Marino side of the layout is in the background.

Photo # 4 A lateral view of the CB&Q #5506 O-4 Mikado on the engineers side making the slow climb up the long 1 1/2% grade of the mainline in the Monterrey Mountains east of San Marino.

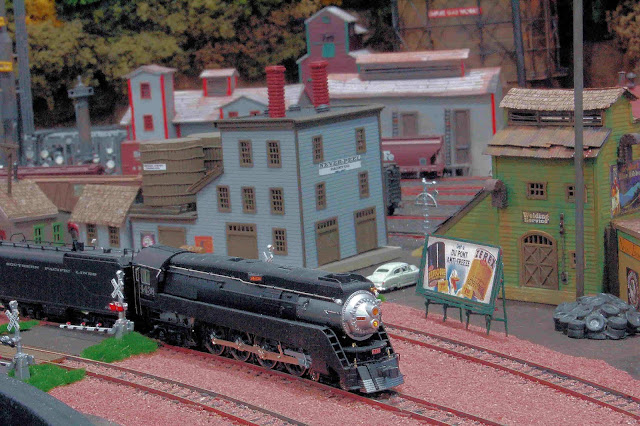

Photo # 5 A lateral view of the CB&Q #5506 O-4 Mikado on the fireman's side of the locomotive making the slow climb down the long grade of the mainline in the Monterrey Mountains. This is an excellent photo of the complex Feed Water Heater and its associated piping.

Photo # 6 A full view of CB&Q #5506 on the fireman's side of the locomotive showing all the pewter detail parts and associated piping. The town of San Marino is in the background.

Photo # 7 A rear view of CB&Q #5506 O-4 Mikado showing all the pewter detail parts added to the fireman's side of the locomotive and tender.

Photo # 7 A rear view of CB&Q #5506 O-4 Mikado showing all the pewter detail parts added to the fireman's side of the locomotive and tender. Photo # 9 A closeup view of the completely painted CB&Q #5506 on the fireman's side in the center of San Marino.